Writer: admin Time:2022-07-18 10:17 Browse:℃

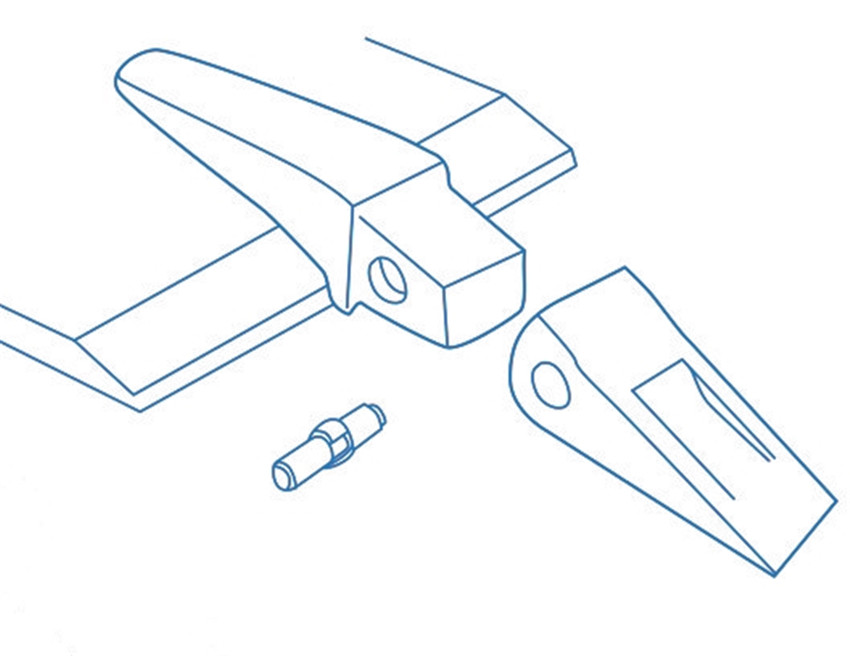

1. Place the adapter on the lip so that the corner adapters are well placed on the corners. Make sure that they sit well on the bevel of the blade

2. Preheat and start welding a few points to maintain the adapters in place. See general welding instructions

3. It is convenient to start welding at points X and Y as indicated in fig. 1 in order to make sure that the defects of the welding that is produced at the beginning of the strings can be eliminated

4. Start Welding in the center of the strap of the adapter welding around it until reaching the same point on the opposite side(area B fig.2). Continue welding strings on each side from the initial points at 25mm from the border of the lip until meeting the first string again(area A fig.2). Repeat the indicated operations until completing the welding with the required thickness.

5. Weld the remaining part between the adapter and the border of the lip. Maintain the same thickness of the string than for the rest of the weldings.

6. Use a grindstone to eliminate the irregularities to obtain a smooth finish, specially in the lower front part

Phone: 0086-13957476951

Tel: 0086-574-88050232

Email: info@tigerget.com

Add: Room#1817, No.158 TianAn Middle Street, Yinzhou District, Ningbo, China